ROOTS POLYCRAFT - INTRODUCTION

Roots Polycraft (RPC) is a part of Roots Group, was established in the year 1988 and a leading manufacturer of Plastic Injection Moulding Components for a spectrum of Automotive and Industrial applications.

We are capable of processing all kinds of Thermo plastic polymers from State of Art Injection moulding machines ranging from 45 to 350 Tonnes, situated in Coimbatore, Tamil Nadu , India.

We are an IATF 16949 certified organizations. We cater to the requirements of plastic components to Automotive components, All Terrain Vehicle components, Off road vehicle components, Components for Textile Machinery, Electrical and Electronic components, Components for Pump Industries, Components for home appliances,Components for Floor cleaning machines and Components for Pump industries.

We have our own Tool Room facility in our corporate factory able to manufacture Injection moulds upto 850T.

We are also specialized in processing of plastic components with inserts with our vertical injection moulding machines.

We have facilities like Ultrasonic Welding of Plastic components and Plastic Extrusion in addition to the above facilities.

HORIZONTAL INJECTION MOULDING MACHINES

In a horizontal machine, the mold and the injection unit are positioned horizontally, with the mold opening and closing along a horizontal plane. The clamping unit and injection unit move in parallel.

Roots Polycraft has 12 Horizontal Injection moulding machines ranging from 50T to 350T and capable of producing components with weight ranging from 1gm to 1000gms.

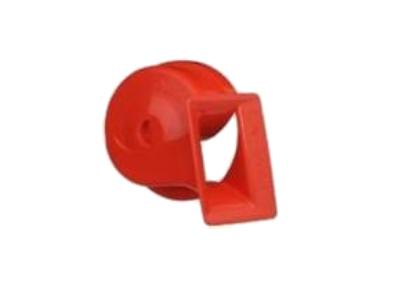

HORN PARTS

USB PARTS

OIL FILTER PARTS

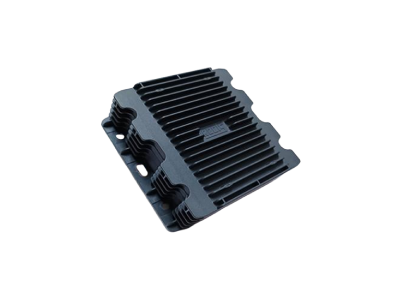

HEAT SINKS

CHAIN GUIDES

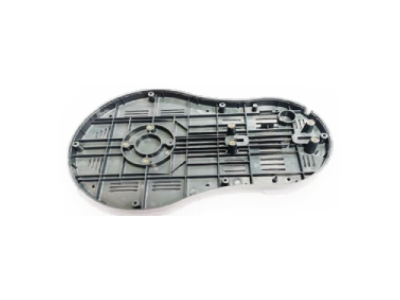

EARTH MOVER PANEL

TEXTILE MACHINE PARTS

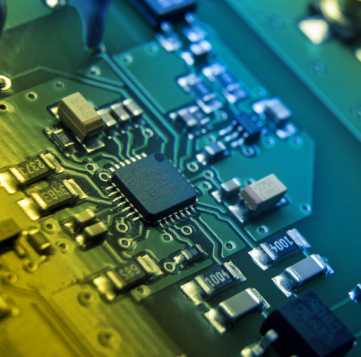

ELECTRONIC PARTS

PUMP INDUSTRY COMPONENTS

FLOOR CLEANING MACHINE PARTS

OIL FILTER PARTS

PARTS FOR HOME APPLIANCES

PARTS FOR MEDICAL APPLICATION

Vertical Injection moulding machine

In a Vertical Injection moulding machine, the mold and the injection unit are positioned vertically, with the mold opening and closing along a vertical plane. Due to its compact design it requires less floor space.This machine is suitable for insert moulding.

Roots Polycraft has 4 Vertical Injection moulding machines with single sliding bed and 1 Vertical injection moulding with Rotary table.

Components produced

ULTRASONIC WELDING MACHINES

Ultrasonic welding is a solid-state welding process in which joining of materials (metals and plastics) occur without melting. In ultrasonic welding, high-frequency mechanical vibrations are transferred to the parts to be joined, which cause sliding one part over another

Roots Polycraft has 4 ultrasonic welding machines , Horn assemblies and Oil filter assemblies are carried out in Ultrasonic welding machines.

Part Assembly produced by Ultrasonic welding

HORN ASSEMBLIES

OIL FILTER ASSEMBLIES

EXTRUSION MACHINES

Plastic extrusion, also known as plasticating extrusion, is a continuous high volume manufacturing process in which a thermoplastic material -- in the form of powder, pellets or granulates -- is homogeneously melted and then forced out of the shaping die by means of pressure. In screw extrusion, the pressure comes from the screw rotation against the barrel wall. As the plastic melt passes through the die, it acquires the die hole shape and leaves the extruder. The extruded product is called extrudate.

Roots Polycraft has 2 Extrusion machines for producing HDPE pipes with 5mm OD and 4mm ID , which is being used in Vehicle horn assemblies and TPE sleeves for protection of vehicle cables.